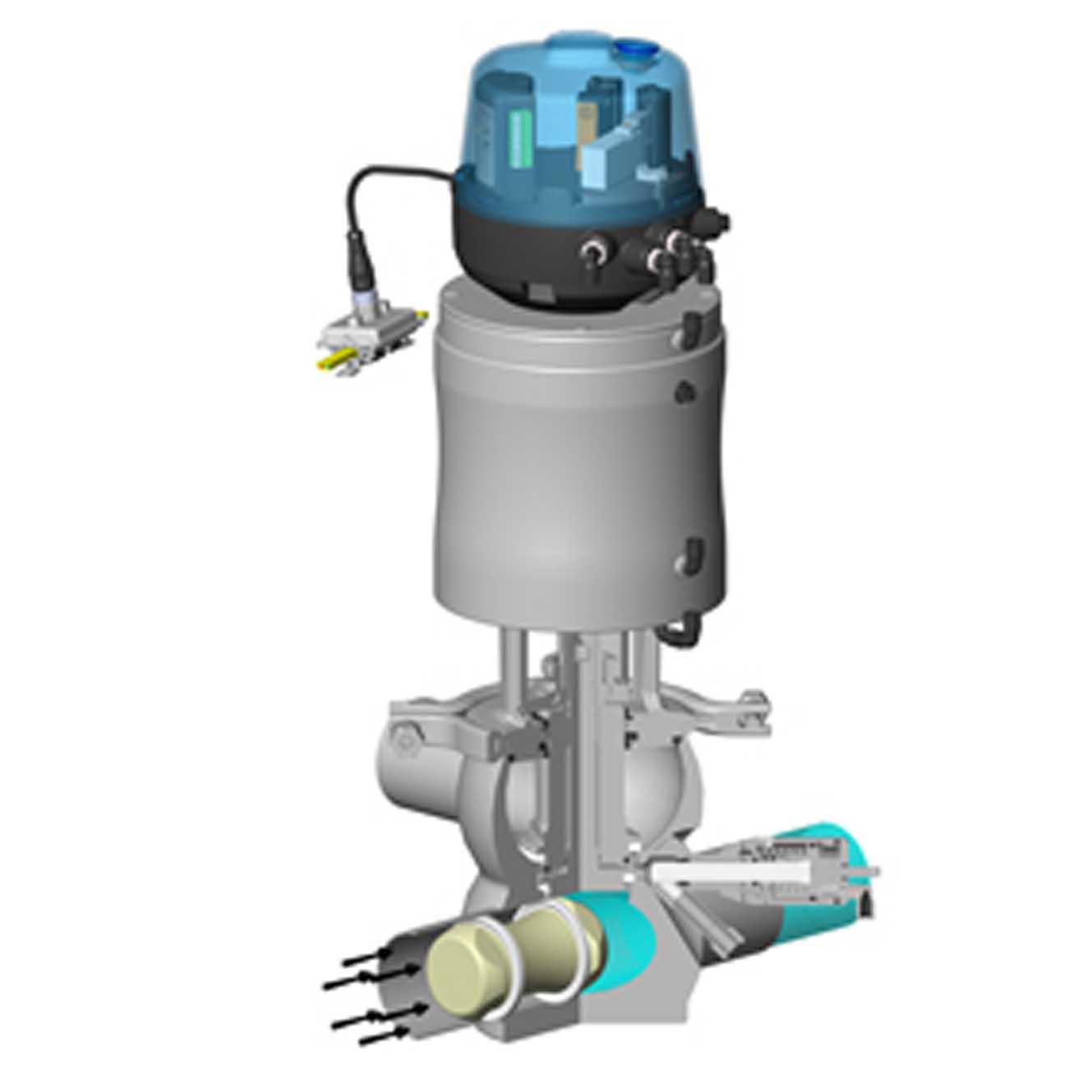

The scrapeable mixproof valve VDCI MC complies with the industrial requirements of the process industries and their economic and environmental concerns.

This technology combines the advantages of mixproof valve technology and those of the scraping systems.

It allows for distribution and orientation of the flows across the valves installed in line with no risk of mixing, with the possibility of scraping the lower channel.

Technical advantages

- From DN38 to DN104

It has the same design characteristics as the standard VDCI MCs (body machined in the mass, PFA floating seals, compact actuator common to the entire range, etc.)

Particularities of the scrapeable VDCI MC valve

- Leak indicator indicating any defect in a leaktightness point between plugs

- Possibility of scraping the lower channel with no leak during operating phases

- Compact leak chamber preventing fouling risks and facilitating cleaning

Benefits

- Excellent resistance thanks to the PTFE microvalve and PFA floating valves

- Reduction in costs of cleaning and waste processing

- Greater flexibility of production facility (limited outage between each production cycle)

- Optimum cleaning thanks to the disk chattering

- Managed consumption of cleaning solutions and water

- Reduction in actuator assembly and disassembly times